@plonkster I have never said this to you before. Out of 10 times, that you say something … about 90% I kinda listen to you.

That Blueprint for 280ah cells and BMS’es is what I’m after for my bank … draw a good picture, give the … Don’t go there … Never go here … and whatever you do … just don’t do that ever …

Took us collectively years to “get” how the different Lead Acids makes and models behaved, what the best settings were … when to use balancers … tuning BMV’s for different types of lead acids.

Each Youtube video one watches, each person who says use these settings, did the best they could, now to add all the best parts together, as it is one thing to test a bank over a week and make a video of what you found, or run a bank lightly, or use X brand BMS with 105ah cells … how does that bank behave after 1, 5 10, 20 years?

Over time, the settings I “saved” for my 16 x 150ah bank:

@plonkster

Bulk: 55.2v

Float: 54.4v

@Louisvdw

Bulk: 56v

Float:54v

@Gman - worked on Daly the best

Bulk: 54.50v

Float: 53.60v

LithiumBatterySa

Bulk: 56v —> Manual: 58.4v max

Float: 55.9v

Charge Amps: 60a (40a per 100ah) —> Manual: 76A

And like Revov settings on a Victron system differs from what SolarMD says for example. Each brand name does it differently, depends on the cells used, how many, and what BMS they chose to use … and to keep it going for >3000 cycles or 10 years warranty, whichever comes first.

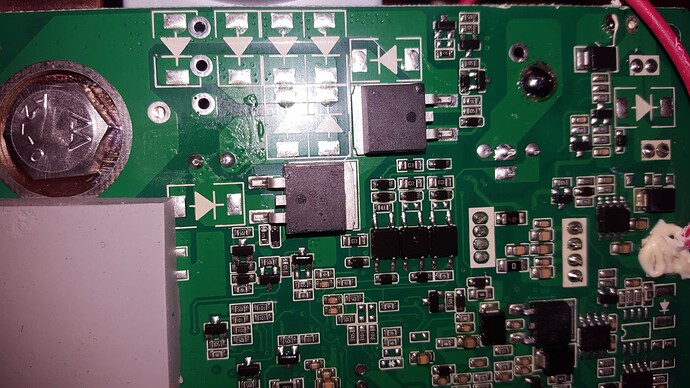

I’m looking for that Blueprint for the really big configurable JBD BMS’e and 280ah cells … you guys tell me what to try, and we try it …