Right, after a LOT of backwards-forward-sideways decisions, talking to quite a few people (engineers too) in and around this batteries inside homes, and what the new regulations willl entail if one does it today, added things like roof structure confirmation and fire certificate or whatnot, I have made up my mind.

Note:

Lifepo4 is safe, very safe.

If you monitor it, maintenance checks, very VERY safe.

BUT …

If a Lifepo4 battery has a “heated temper tantrum”, the reaction is unstoppable.

Understand that.

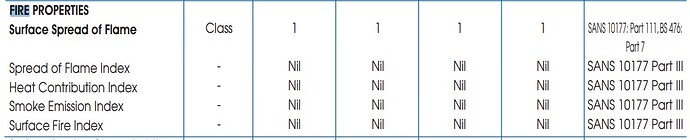

Now, if one wants the batt inside the house today, the regulations apparently are “out there”, not yet official (presume lots of heated (pun intended) debates going on), you would need a 120minute Fire Resistant battery case, with a max limit, if memory serves, 10kWh(?) or such.

17kWh like I have, nope, not allowed.

Looking at it all, my view, 120min Firer Resistant battery case, that is a “band-aid”. Straw grabbing.

Why?

The gasses released. They can kill you.

But far worse than that, and this is the other “thing” with lifepo4 batteries, ventilation.

The gasses can build up and that is where I deduced, the truly dramatic issue is, with the ongoing “heated temper tantrum”.

That vid of the fireman walking away from the closed garage door, next moment him ducking as the door barely missis his head coming past him is stuck in my mind.

So, that is some background.