what is more important regarding mppt’s, Voc or Vmp, especially in cold weather.

Voc is the open circuit voltage which means it is the voltage the PV panel will measure when it is not connected to a circuit. So normally this will not be the case in a working system. But say you trip the PV breaker/fuse then Voc will apply. You might hit that high voltage around full sun (mid day for a norht facing array) if you then close the breaker or reconnect the fuse, but it will quickly be pulled lower by anything using that power (charging the batteries, using the lights, etc.)

Vmp on the other hand is the the maximum power under load. The load is trying use the power, pulling down the voltage. So you normally see that Vmp is about 75% less that the Voc values. Except when there is a break (circuit breaker, fuse) this would be what you will see in your system.

Yes. I think the important thing about MPPTs is they don’t abruptly draw power. They start slowly and ramp it up, until they see the power come down again (meaning they have gone OVER the peak), then they backtrack and then they balance the power level around the peak (like a surfer on a wave).

So for a few seconds right at the beginning, the MPPT sees Voc.

The MPPT generally has some kind of MOSFET switch inside. You need at least one (for an async buck converter, where the other switch is a diode), but most of them will have two MOSFETs, and some may even have more (for polarity protection). However many there are, this component has a maximum operating voltage. Go above it, and you will damage it.

And hence, you should not expose an MPPT to a voltage higher than it is designed for, and that means keeping the Voc of the panel lower than the rating of the MPPT.

The Voc is however temperature dependent. Normally a PV cell makes 0.5V at max power, and 0.6V (ish) open circuit, but if you make it cold enough, it can go as high as 0.7V per cell.

What you need to do is look at the specification of the panel. They are rated at 25°C, but there is a temperature coefficient that tells you by what percentage that will change per degree centigrade, so you can work it backwards and find out when you will exceed the Voc of your MPPT.

in my case, the Voc of the panel is 46.8 volts and the Voc tempreture coefficient is 0.29% / 1 degree, so for 10 panels the total Voc is 468 volts and if I use 0 degrees as the ambient temperature, i would have to add 33.93 volts, for a total of 501.93 volts, whereas the limit for the mppt is 500 volts.

So for Cape Town, is it safe or am i taking a chance of blowing up the mppt, the max i saw was 375 volts a few days ago, that was with 9 panels in the string

The reason for wanting to add this one panel is that i have one panel left over after some changes to the other string and you just loose to much trying to sell used panels.

It comes down to statistical analysis.

As per ploksters’ description, your MPPT will actually see Voc in the mornings, just before the MPPT kicks in to drive them to Vmp. We have this in industry with the central inverters.

So a few things. Is the MPPT Vmp 500V rated or is the MPPT device 500V rated? There is a difference there. If your device is 500V rated (maximum allowable voltage), you would have to look statistically at your set up.

In the winter how often do you actually reach 0 or near zero? How long would you be at 0 while the sun shines? As soon as the sun hits the modules the temperature increases. So you could have ambient of 0, but modules is as 2 or 3 degrees and thus Voc will be safe.

Then also, while a MOSFET might have a maximum 500V rating, if using a high quality product then you would be looking at a 500V rating +some safety margin.

So, from my perspective, you would be safe but will void your warranty if the supplier can prove that above 500V was achieved (even if 500.01V).

When the batteries are charged and load is low, the MPPTs will ramp down the current by going towards Voc - so you will actually see Voc on your MPPT input more often than what you would expect.

Also, don’t bank on much of a safety margin on the semiconductor ratings. Drain-bulk breakdown is tightly limited by the process spec, so there is no real need to build a safety margin into the devices.

But it would take a fairly pathological combination of factors to get you over the MPPT limit. You need cloud edge effect near noon to get anywhere near the rated solar influx that far South plus sub-zero air temps (which are almost impossible next to the ocean).

So while no one can guarantee that it will be in spec, it almost certainly will be this side of the apocalypse.

On one of the sunsynk videos, Keith mentions that the MPPT is rated at 550v but they (sunsynk) rates the mppt at 500v on the inverter specifications.

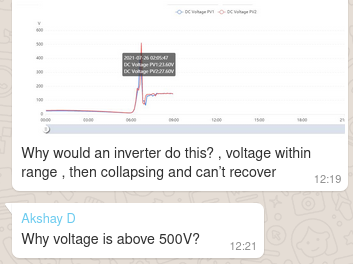

Hah… This was just posted on the Deye manufacturer support group:

First question - Why is voltage above 500V.

Probably a prelude to an out of warranty repair…

I would personally not take this chance. I know there are lots and lots of things that needs to line up perfectly to get there, but I would not gamble on zero.

In your case, you have 500-468 = 32V headroom, that is 32/468 = 6.8% headroom. Divide by 0.29% gives you 23.5°C below 25°C, which is more like a minimum of 2°C.

As Phil often points out, it takes a lot of energy to get below zero (because it has to suck out all the energy from the water in the area first), but it’s a fairly linear exercise above that.

I would not chance it if it was me. But I think this is very much a personal opinion.

The coldest I’ve measured in Somerset West was 0°C. I’ve lived here for 17 years and that happened once. So perhaps it’s a bit more than just personal opinion ![]()

You guys are right, it would be easier to take a loss on the panel and not have the few hundred extra watts then to have an out of warranty repair and the downtime.

Well, make sure what the absolute max is. Some of them stop charging above some limit (eg Victron 150V chargers will stop above 145V), but they are only damaged a little later.

If the sunsynk can tolerate 550V (but stops above 500V), then you’re good to go.

" No that’s not true it could probably tolerate up to about 520 absolute maximum 550 it would shutdown".

The above is a reply to my whatsapp to Keith Gough ( ceo of Sunsynk ), I asked him if 550 volts is a hard limit for the Sunsynk

This inverter did recover after a power cycle. So it was some sort of voltage clamping mechanism to prevent damage.

@plonkster, based on Keith’s reply above, would you say I am good to go.

Today after the early afternoon peak on the NE array, the voltage hit 382 volts ( 9 panels-total Voc = 414 volts)

I have no idea. If he is right, yes. If he isn’t, no. His post seems to indicate it is based on hearsay. I’d like to see it on a spec sheet before I put my neck on the line ![]()

Edit: OK, I read your post properly. If you got it from the horses mouth, you should be good to go. Take screenshot of the whatsapp in case it fails and the warranty person decides to use it against you ![]()

We really need a tear down of this inverter when one of them fails just to see the actual components used and check the ratings from the component manufacturer.

The fact that they could increase my MPPT from 18A to 22A via a software update indicates that some of the components are probably over spec’ed.

I’m also pretty much peaved at this upgrade as at the time I opted for panels at 9A per string when I could’ve had bigger panels at 11A to 12A.

Decided not to take a chance with adding another panel to the string, so selling it to a forum member, who will make good use of it