- What goes into planning and how to do so (Fail to plan, and you surely plan to Fail)

Planning, no assumptions, getting into the data, requirements and understanding of the system. There are opinions, assumptions and data, you pick the trustworthy one…. Where do we begin? We begin with requirements, see, all those questions. For this purpose I will keep it simple. The off-grid system will be the design model.

Let’s start: What are your plans for the Solar install? Off-grid, I want to go. How much energy do you use? 7500kWh per year and I consume 500kWh per month on average, accept Winter time, for those 3 months I consume on average 1000kWh per month. Are you connected to the grid and do you want to remain connected? Yes on both counts. Do you have a generator or think you need or want one? No, since I remain on the grid, just don’t want a monthly bill. After the pandemic, lots of people are working from home. How did this change your energy consumption? Did more consumption move to daytime or is the early evening energy hump now bigger and longer?

Now we can discount a generator, and not worry about blackouts or bad weather since there is a Utility grid connection. Do you have a CoC, if not please get one prior to this installation. We cannot install anything, if the current house wiring is not up to standard. Don’t take this in a negative way. You need to have wiring that will not burn your house down anyway, that would kind of not be nice, family and all. How will you know after the install, if the installer did a half decent job of the installation? Or will you have to pay the Solar installer extra to fix your wiring issues, delay the project and charge extra, not good.

On to the design.

We need to generate enough energy for the winter months, that means at least 1000kWh per month or 33kWh during the 7 or so hours of sunshine per day, hopefully. This is worst case scenario, apart from bad weather but we can charge batteries from the grid if required. This means we need at least a 6kWp system to counter some losses. If we add battery charging into the mix while carrying the house load during the day, as we should, this would grow to about 7.5kWp in panels.

For the inverter sizing we need to understand the peak loads we normally have. How many appliances are running simultaneously is the bigger question? What are their combined power requirements in kW? Can you reschedule when they run to be able to reduce the peak load? The inverter must be able to supply the peak load, or it will trip on overload, or worse get damaged. You have to get the name plate wattage from the appliances, or measure it, then see what runs together and how many Watts this is. The more you can reduce the peak power demand, the smaller the inverter required.

However, the inverter must be able to accept the panel string voltages , string voltages must be less than max inverter PV voltage input, or it will be damaged. Also, the Charger for the battery must be of sufficient capacity to charge the battery fully in reasonable time. Bear in mind, future expansion, and normally the inevitable bigger and more powerful inverter that will require. If you buy just enough inverter for today, you will replace it when upgrading in the future. Other inverter criteria to consider is: Grid-tie or not (in off grid situations this means a Micro Grid and a whole different discussion, and would also need a Hybrid or Solar/Charger/Inverter), Hybrid or just an Inverter charger or and inverter charger with Solar input. There are modular systems as well, Victron is one example.

So we need about 7.5kWp panels or 20 x 380Wp. Then we need an inverter that can handle at least 500VDC and 2 strings of 10 panels each. You can go for bigger wattage panels like 595W with lower voltages ie 40-42 Volts or really any panel combination that will be suitable but not exceed the string voltage of the inverters. Now we have an idea of what and how many Panels, and the inverter sizing. There are online web resources that explains how to factor in temperature and other parameters when doing the calculations. Next will be the storage to make this an off-grid system (or we can choose and Energy Storage System) ESS as we are Utility grid connected, remember?

Two examples of ways to calculate: VE-MPPT-Calc- and String Sizing Guide: How Many Solar Panels Can I String Into My Inverter you can search for these online.

We need about 26.5kWh as per the simulated model we build previously. A few points to consider and bear in mind here.

The tilt and azimuth angle of the panels are paramount in determining how effectively, really how close you get to the max panel output, they generate energy or put differently, how efficient they generate those Amps. Consider that once the panels, and the complete system for that matter, are purchased, the energy will be generated for ‘free’. No it’s not free as you had to buy the equipment, but apart from that, the energy is free. You do not have to buy new energy every month on top of the equipment purchase, unlike gas or fuel oil or Government provided Utility grid energy. So spending a bit more here to get your panels orientated properly for max efficiency, pays off handsomely for the next 20-50 years. What for 50 years I hear you ask?

Panels degrade over the first 10 to 15 years and can loose as much as 20% of nameplate capacity. There after they remain mostly stable with very little degradation. If not damaged by some physical means, they can remain productive for 50 or more years, essentially providing totally free energy after the break even period. There are known panels older than 50 years still generating energy today. Panel design accounted for. Inverter design done. Now for the battery part.

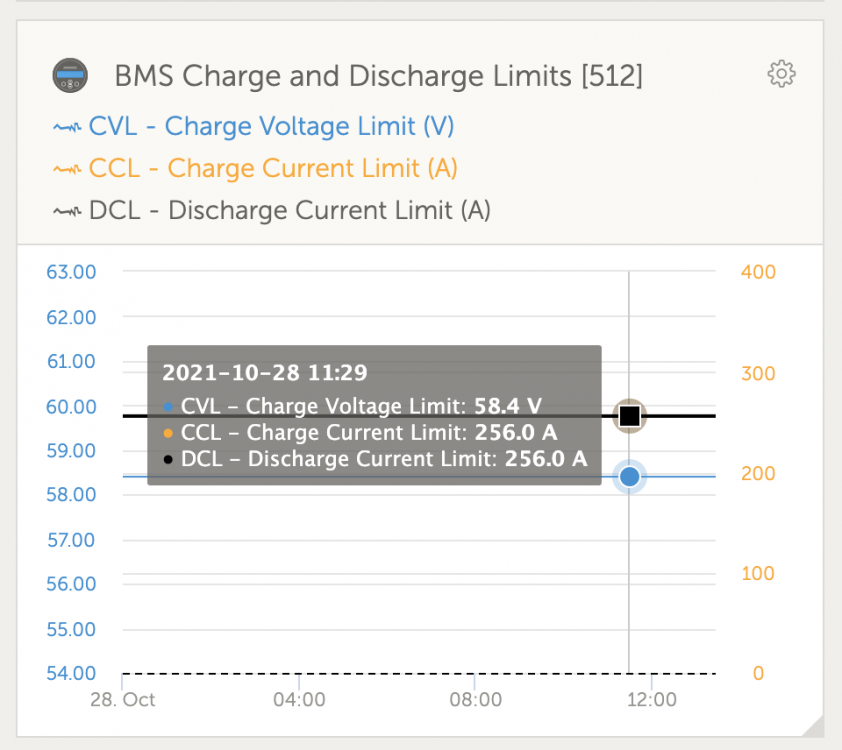

As we could see when comparing the barebones system with the off-grid system, we need batteries, many many batteries. Well, really a battery with large energy storage, not always many batteries. So this gives us the first clue of what is required to select a battery system, capacity. Other factors are Cost, the Volume the battery system will take up in an area, the Depth of Discharge or how much of the energy is normally available to consume, and no you normally cannot consume 100%. More parameters are the charging and discharging time and the Ampacity the battery system can deliver, or accept. There are Low Voltage (LV) and High Voltage (HV) battery systems on the market. Your Inverter needs to support the HV or LV battery and you cannot use one technology battery on and Inverter that does not support that. A few more parameters for consideration are: Battery chemistry, if they can be used in parallel, C rating and what their max charge and discharge currents are.

Most Inverters can communicate with the Battery system. This communication is of vital importance. Now, can an Inverter use a battery without comms, indeed yes it can. The problem however is that you must rely on other means to configure and protect the battery system as well as configure your inverter. With the cost of these things, it’s better to opt for a system where they can communicate.

Back to battery capabilities. Let us consider the following scenario: You have a 5kW Inverter, a very popular size. The 5kW (5000W) is the capability at the AC output of the inverter. Some inverters can exceed that 5kW by a certain percentage for a certain period, normally a few seconds or maybe in some cases even by a few minutes. Also not that these numbers are at an ambient (room) temp of 25 Celcius. You would have to reduce the output to some number below 5kW for higher temps, normally given by the manufacturers as a derating at temp, number. So now on to the battery currents. Normally, best practises dictate that 24V battery systems be limited to 3kW inverter sizes. Can this recommendation be exceeded, yes of course, but not without consequences. Thicker battery cables, shorter cables (impossible the bigger the battery bank gets) and much more difficult to make and costly to buy, wiring.

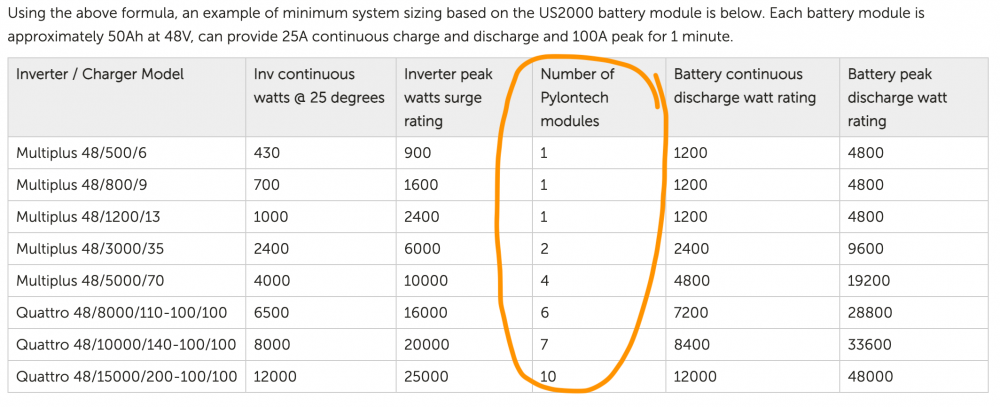

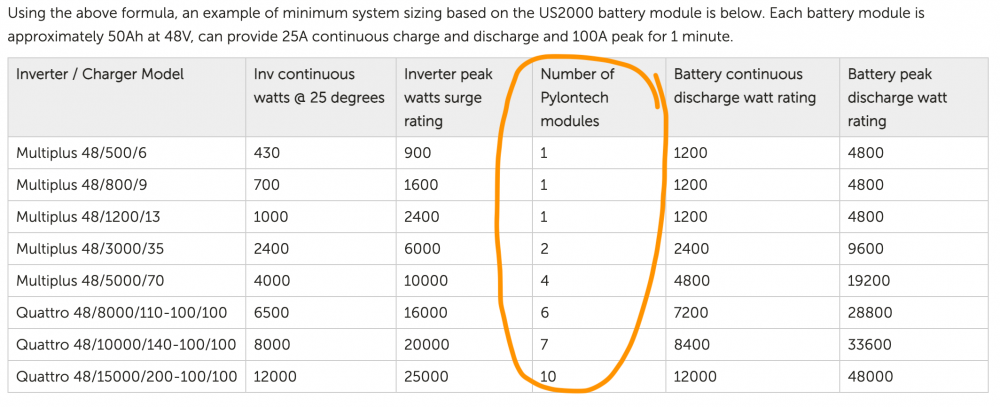

For inverters bigger than 3kW, 48V battery systems or higher voltages, are recommended, no required. Let’s calculate some. 5kW at 240V means 20.8Amps at 240 Volts. On a 48 Volt battery the current draw would be 105 Amps, not accounting for all the losses. Lets say your inverter is 93% efficient and you battery bank & cables loses 2% for roughly about 115 Amps at 48 Volts, including losses. So now you would need closer to 240-250 Amps from a 24 Volt battery system, cable thickness, more than your wallet any day till Sunday  . The below is a recommendation from Victron as per the minimum config for Pylontech, as an example. Consider this more of a standard minimum requirement. I am using this merely as an example for configuration and to illustrate the point.

. The below is a recommendation from Victron as per the minimum config for Pylontech, as an example. Consider this more of a standard minimum requirement. I am using this merely as an example for configuration and to illustrate the point.

This type of configuration, and specifying the number of battery modules, are normal for all battery bank manufacturers and would be a similar requirement from most inverter manufacturers. You may void both your inverter and battery warrantee if you exceed the specifications as both pieces of equipment may be damaged due to misuse. Do so at your own risk. These are just facts.

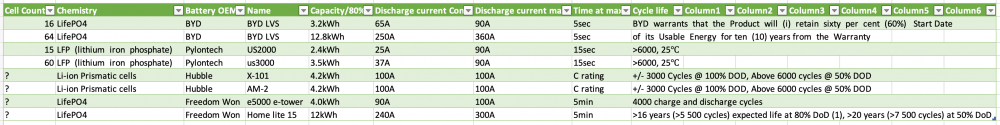

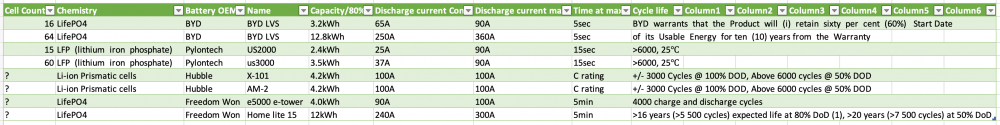

Battery modularity is a good feature. It somewhat ensures future additions to allow expansion of storage capacity. This is not garanteed however. Being able to parallel 48 Volt batteries is desirable. Just some battery comparisons for the local market. All these were available for purchase during the plandemic year of 2021.

Here you can see a summary for various modules. Theses specs were current at this time, they may be changed at any time.

It is abundantly clear from the above that there are major differences between manufacturers and modules. This is not a recommendation of any kind, merely to show capabilities. Pick a system that firstly can communicate with each other if at all possible, only ignore this as a real last resort. Secondly ensure that minimum specifications are met, this is not optional but required. Your system will have a long happy life, and so will you as your significant other will not attempt murder

Next time:

- Based on the previous, plan a system’s PV Panels

PS: my spelling sucks

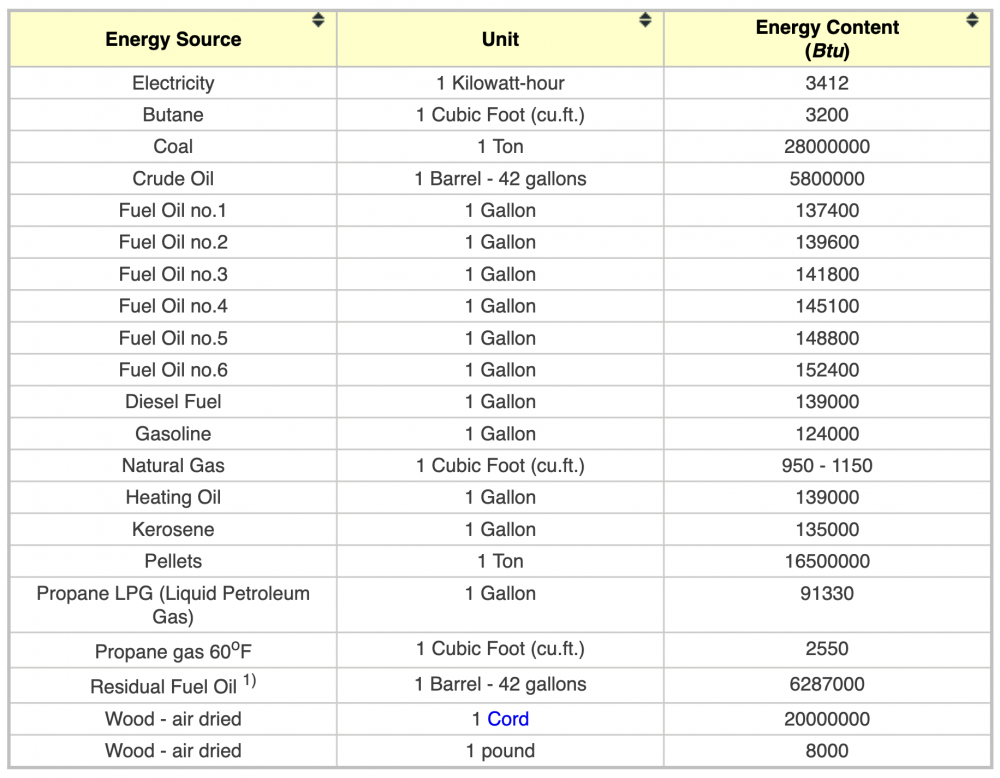

, or you can use a Gas stove. All these alternative fuels for supplying energy can be considered and used, depending on your requirements and lifestyle and need to save on the Solar PV systems costs. This could mean you can afford a smaller and less expensive system, if you offload some of the energy to other types of energy for those tasks.

, or you can use a Gas stove. All these alternative fuels for supplying energy can be considered and used, depending on your requirements and lifestyle and need to save on the Solar PV systems costs. This could mean you can afford a smaller and less expensive system, if you offload some of the energy to other types of energy for those tasks.

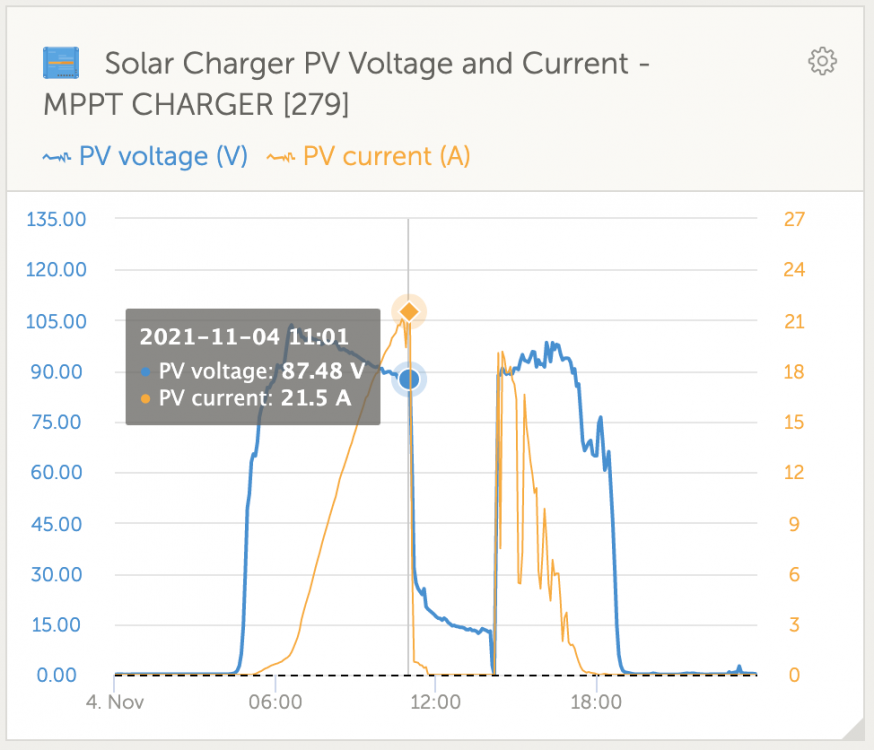

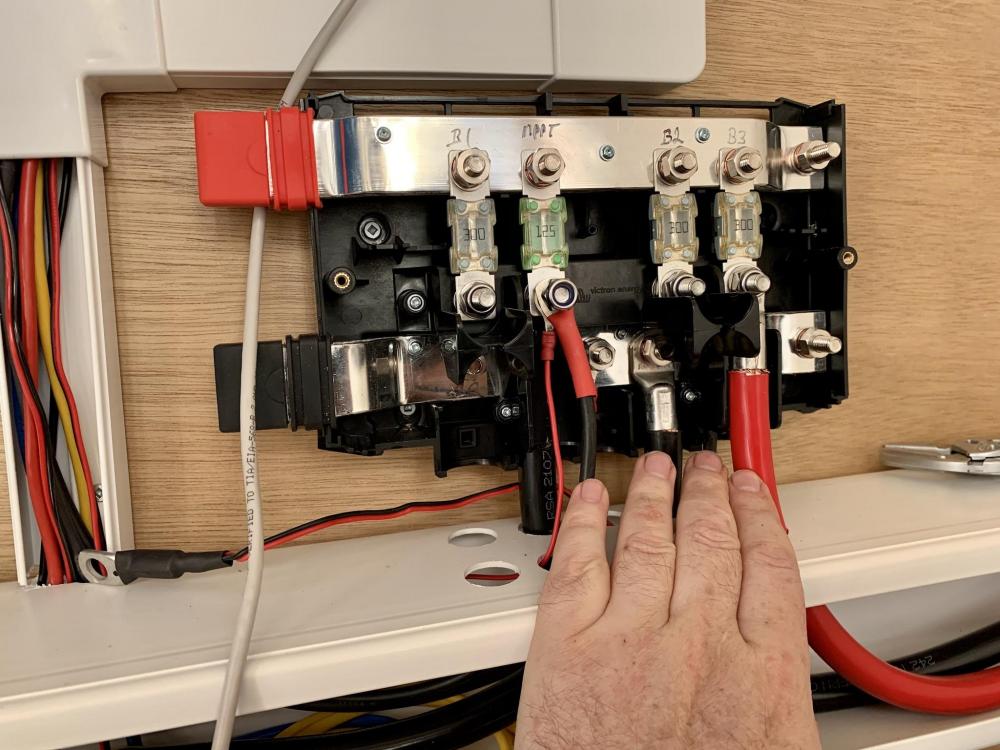

hot. When purchasing the fuses, the oversight was that of forgetting the the DC coupled system would be configured as 2 x 3 panel strings in parallel for double the Amperes. See was easy as that your fuse becomes to small

hot. When purchasing the fuses, the oversight was that of forgetting the the DC coupled system would be configured as 2 x 3 panel strings in parallel for double the Amperes. See was easy as that your fuse becomes to small  or should that be short…

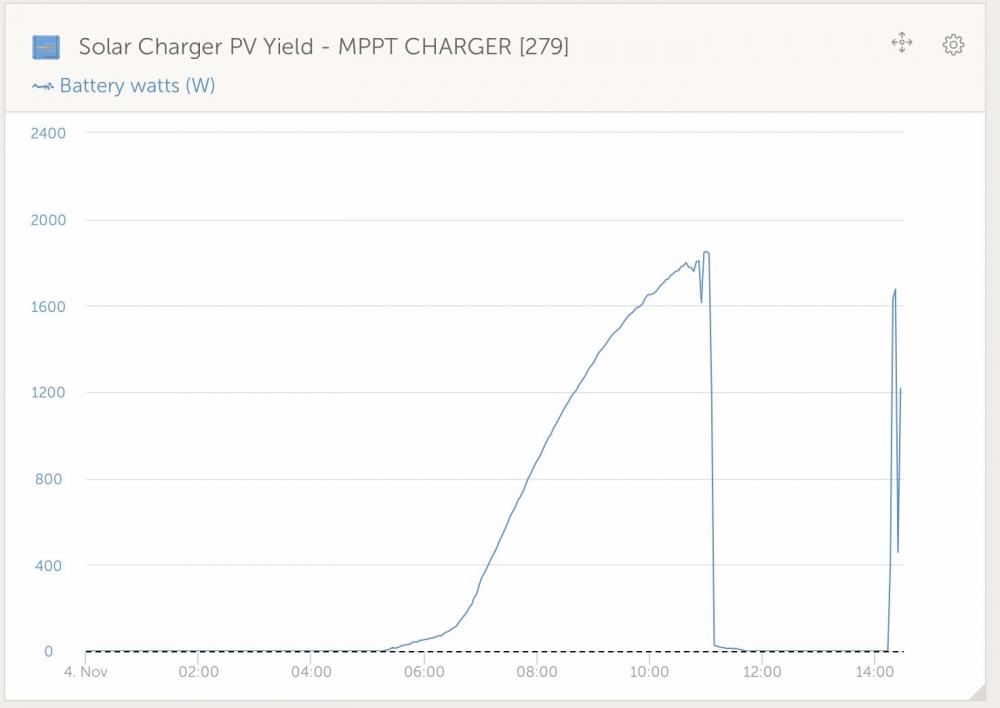

or should that be short… . New fuses on order. In the meantime, the big ass fan on the fuse holder and MPPT keeping things cooler and the fuse not blown.

. New fuses on order. In the meantime, the big ass fan on the fuse holder and MPPT keeping things cooler and the fuse not blown.