Ok I went with these and will see how it goes.

Hehehe… I’m going to modify that. A developer deals with support as a last resort. If it is not in the documentation, the installer could not figure it out, the reseller could not help, and the first level remote support guy is stumped too… then it goes to the guy who actually built the thing. That is kinda nice, I think, you always eventually get the help you need, even if it takes some time!

Occasionally (like this morning), something goes through all the steps and ends up with the developer, who then tells you switch off the “Has DC System” switch you moro^H^H^H^H^H^H^H^H^Hdear customer.

(Note for the non-unix/linux people, on really old keyboards that didn’t have a backspace, ctrl+H would backspace a character).

In all my career in software support, the ONLY person that shall speak to a developer, is the last line support person.

Why?

- That the last-line support person can learn what to look for WITH the developer.

- More importantly, the developer can spend all their time on their core job - read, get less distracted with, as you posted, things that SHOULD have been part of the shared knowledge/experience with all the people before the developer.

Know what, that last-line support person BEFORE the developer, ideally must be a wannabe developer or a new developer in training.

Protect your core developers at all costs.

Ps. I taught clients who want to learn, how to run SQL scripts on their live database. Even fix their own staff’s repeated mistakes. … that solves a lot of repeat mistakes btw … cause sometimes you create more work/support (cans of worms) forcing fewer mistakes via the software. Somewhere people have to take some responsibility.

Now before people go into a “hissie fit” … that data, backups being on spec … is the client’s data.

They have a “right” to access it themselves if they want to learn.

I tried it, sometimes clients seriously impress the socks off of you. Sometimes you NEVER go there. The trick is to know the difference … but it takes BIG “round things”. (… just to be PC)

Honestly, sometimes the developer can solve it in 5 minutes.

I just returned from a case where someone set the AC input limit to 1A, and then didn’t enable PowerAssist. Second case today that should not have made it past the installer… yet it made it all the way to a developer.

But, I am more than just a developer, so I shall not complain.

The one thing that really makes things complicated is the Battery SOC on Reset … set it to Keep SOC.

When your BMS is switched off and it is switched on again, mostly it is better to start with the last SOC, as normally your batt is off too, OR, it is a temp situation.

For longer periods, the batt is still left on, just BMV is off, it is easier to sync it back to 100% than to wait for it to “catch up” again … or to intervene and do it manually, setting the SOC.

My 2 cents.

There is actually a good solution for this, and that is to keep the BMV on. The BMV’s shunt should be installed before any switches and fuses anyway, and it has that little red wire that powers it from the positive side, a little wire that has its own fuse, so no need to protect it with the large system fuse. This is also how you get the most accurate battery voltage.

That way, you can turn the entire system off, and leave the BMV running.

If you do turn the whole thing off, well, then remembering the last SOC is probably the best way to go about it.

(You can also write /Soc on dbus… it actually works… for those who know how to do that).

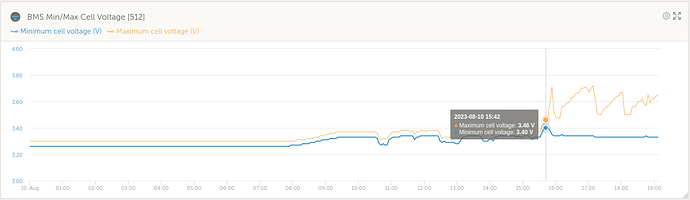

I made this shot last night with the plan of posting it here later. This is what I look for. At the deviation point, how far away are the cells from each other? If it is this close above 3.4V, you’re almost done balancing.

I tried it, stopped charging at 96%. Needed to push the voltage up to 55.4 and the battery quickly reset to 100%. Will try 55.3v next/

I am not quite sure what you are saying. Can you maybe elaborate?

I’m saying that often the exact point where the shoot-out happens tells you more than the flat lines following. All the cells were fairly close together until they got to 3.4V, which according to the way most BMSes determine SOC, is around 95% full. After that the balancer goes into full drive and in the case above, the BMS lowers the charge voltage/current/etc… and the data that comes out after that doesn’t really tell you how close you are.

That little window just as one breaks away… that tells you how close you are.

This is not advice … these are just my views on what I know today:

My focus, in all my posts on this, is after it “breaks away”, that is the key to how well the cells are in balance, if they are of the same resistance, and also why one ideally should stop at 3.45v per cell.

Also what Andy saw, for DIY batteries that is, is why he makes a case for only starting balancing after that point.

And also why I add, if the Delta increases past a set point, a cell/cells are shooting out (gets worse over the years I would bet), then the remedial action can start taking place way earlier, as it can start anywhere on the flat curve, especially over time/usage and age.

Just my 2 cents.

So there is progress, albeit slowly. How long have you been busy with this? i assume you’re testing for other stuff but also trying to get the cells to balance whilst at it.

Just a little feedback from my side. Since I used the lithium parameters on the BMV, it is has been pretty much been spot on with the BMS. Been a couple of days now.

I cant believe I never even thought about this. Thank you as always for all you clever okes willing to help!

Just over two weeks now. This is my new house battery, but it is also here because it has some other new features that is in testing. Those features are unrelated to the BMS and the rest of it though ![]()

Whilst on the subject of cell voltages and top balancing with cells connected in series:

Can I assume that Li-Po cell voltages won’t necessarily be the same when the battery is not fully charged but this is ok as long as they balance at the top when fully charged??

Are you asking if you can use a LiFePO4 balancer on a LiPo (Lithium Polymer) cell? It probably won’t work very well. It will start balancing too low down.

I think the process it the same for other chemistries too. Even lead acid. You can run a balancer on those as well, but generally you don’t want the balancer to activate before 13.8V (on a 12V battery).

You can technically balance at any voltage whenever 1) the battery is charging, and 2) there is a significant delta between two cells. It isn’t a requirement that the battery MUST be at a higher voltage. I think @TheTerribleTriplet will like this paragraph.

It is just that in practice, because of the flat voltage curve, that’s where the imbalance shows up most clearly. If you keep in mind that temperature and other calibration differences also means you cannot necessarily detect imbalances accurately until there is at least a few tens of millivolts of it… it just follows that you want to activate the balancer only when a decent delta shows up… which is always going to happen higher up.

No. I’m referring to LiPo and this is the balancer PCB: Other Electronics - Battery 18650 Li-ion Balance Board 4s 4.2V **LOCAL STOCK** for sale in Cape Town (ID:592046816)

It activates at 4.2V switching a resistor on that’s connected to the battery.

This is all good and it does it’s job just fine…

But my question is what about when the battery discharges. What discrepancy in voltage can you expect between the cells and is it consequential??

It will differ yes … not all cells are 100% perfect.

But must not be too far out either cause a weak cell, as it discharges faster, will also cause drama.

By how much?

Depends on how well the bank was top-balanced, the cell’s quality, each cell’s resistance, and obviously the lithium tech used.

Some random comments from my limited experience playing with mismatched packs.

- Do not balance on the flat portion of the curve.

Cell voltage in this portion of the curve is more dependent on secondary factors, like temperature distribution across the cells, connection (crimp/solder) quality, etc. The pack spends far more of it’s life in this operating regime, and you end up ‘balancing’ on other factors rather than charge state.

Effectively you (at least I did) end up introducing more of an imbalance than what you can fix at the top of the charge cycle (due to the relative times spent in the flat/charged portions of the curve).

Especially with mismatched packs, it is important to only balance on the non-linear portions of the curve.

Ideally, also only balance under charge. Under discharge, other factors dominate cell voltage. But not for long, as voltages drop very rapidly to the flat curve, so you don’t spend much time in this regime.

- Round Trip Efficiency (RTE) is king.

You can use whatever you want in series, and it will work (if your BMS is good). You will just be limited to the capacity/capability of the weakest cell.

BUT newer/fresher/higher capacity cells generally have higher round trip efficiency.

Let’s say you have a fully charged 2S pack. One cell as 99% RTE and the other 98% RTE. Discharge by 100Ah and charge 100Ah, then the one is at 99% charge (requires 1Ah more to fully charge) and the other 98% (2Ah more to fully charge).

Continue charging until the most efficient pack is at 100%, and the other pack still needs ~1Ah to fully charge.

As long as the balancer can balance this 1Ah difference every day, you are fine. If it can’t, then the imbalance just grows more every day, reducing available capacity.

When charging off solar, you often only have an hour or two each day in the balancing range, so you need a fairly beefy balancer to match them. The wussy balancers in Seplos/Daly/Tiaan Power BMSs are generally insufficient to handle the imbalances inherent in 2nd life (or otherwise mismatched) packs.

The entire purpose of balancing is to use the maximum capability of the battery pack. You want all of them to be full simultaneously. You don’t really care if one of them is empty before the others (at least, not in the simple cheap case… there are exceptions… I am ignoring then for now).

Therefore, if during discharge one of the cells drops 0.1V lower than its neighbour… who cares. Balancing at this point doesn’t help to make any more energy available.

But at the top it matters. If one cell reaches 4.2V before the others (using LiPo voltages here), then unless there is a balancer, its neighbours cannot take any more charge. That means whatever uncharged capacity exists in the other cells is unused. Which means you are losing out on some capacity you could have had.

Now for the exceptions. The same scenario exists at the bottom, when the cells are almost completely empty. One cell may be dangerously low, but if I can bypass that cell so it doesn’t discharge further, or transfer some energy to it from other cells… I can extract more energy from the battery. So again, the balancing is about getting more energy out of the battery.

That’s why you only balance on the top- and bottom ends. You do it to get more energy into- or out of the pack. No more.

It is significantly easier to balance at the top, and if you select cells with similar capacities, you can mostly ignore the lost energy at the bottom end… which is why this is the recipe used by most: Balance only at the top.