Interesting results…

Good report, Pylontechs seem to be up there with the best.

The big issue re batteries is that in 2-3 years time after your initial purchase you may not find the newer batteries being compatible with the older existing ones. One has to buy capacity in 1 go, trying to spread it over a few years will be difficult as in the US3000A/B and the newer US3000C versions.

Potentially ignorant question: Is the US3000C not compatible with a bank of Bs?

If I wanted, in 2 years time, to buy a few more Pylons to add to my 4 US3000Bs, would I have to get/find more Bs?

Edit: This suggests the C “should” work with “older” Pylons:

The US3000C can be used with an existing battery bank consisting of older US3000 lithium-ion batteries but the US3000C needs to be used as the master battery .

They are compatible, there are however cabling changes between the inverter and the new “C” master. There is a batch of 3000C that are problematic though.

The point I was trying to make is that the battery providers will have to improve their technology and may not be able go kep new batteries backward compatible going forward.

In 3 years time don’t expect the US3000K version to be compatible with a “B” version…

True, makes the whole “when should I add more batteries” question a bit more of a head-scratcher…

Soon there will be a “pre-owned” market for lithium batteries. Personally I would not be against picking up another older 3000B or 2 at a good price which I know will be compactible with my existing batteries (age, usage and cycles).

I don’t have any big Li_ion battery packs but this story scares me off.

Once again the decision of the way to go is definitely not a no brainer!

I’m not too bothered about the compatibility thing. Yes the data cable communicating with the inverter changed. Only the master battery needs that anyways.

It really is in Pylontech’s best interests to ensure backwards compatibility, as they know that people with solar tend to upgrade. The electrical side of the batteries will be compatible (unless Pylontech goes the 16 cell route in revision D for example or change their Lithium chemistry) and to make the BMS communicate shouldn’t be a feat impossible to overcome.

My uneducated view is that in reality, Pylontech will perform even better than it does in those tests (relative to other batteries), because of their absolutely anal BMS. Limiting continuous charge/discharge to max 0.5C will be great for the SA environment with ambient temperatures already on the high side. Other manufacturers are happy with 1C, which is per my understanding within spec of the LiFePO4 chemistry, but will undoubtedly create more heat.

Guess it also depends on your amount of batteries, the amps of your MPPTs, and the amps your inverter can draw, whether the 0.5C or 1C limit will be hit, but in a like for like comparison I prefer the limits on the Pylontech.

Haha. I really dislike the fact that the BMS does a hard-off when you even touch 54V. And because it is a 15-cell design and the recommended charge voltage (53.2V) is already a quite high 3.55V per cell, it overvolts really easily and leaves little room for calibration errors. One big improvement would be if instead of a hard on/off they rather block charge or discharge.

I have now worked with two batteries that use this method. The first one was the new BYD Premium LV. The other is the BSLBATT, also a fairly new entry into the local market.

How it works: The battery has two directional switches (FETs), so that it can stop charge from entering the battery if it is really full, or it can stop charge from leaving the battery when it is really low. If you block charge (for example), the battery can still be discharged and it remains connected to the DC bus.

What is so excellent about these is if you push over the maximum voltage the battery would like, what you will see is the DC bus itself have a different voltage to that reported by the battery. In testing, I pushed the DC voltage to 61V, while the battery neatly divorced itself from the artificial mess I created somewhere around 59V. When drawing power from the DC bus again, this deflates really quickly (because it all lives in a few big capacitors) and as the voltage drops down the battery seamlessly picks up the load… because the discharge switch is still closed.

Yes, in their own interest to ensure backward compatibility.

I see in the linked article they say " * The Sony and Pylontech battery packs have so far demonstrated superior capacity retention; that is, their claimed capacity didn’t significantly diminish over time."

My own bank of Pylontechs have only dropped 1% since the installation of 4 batteries in March 2020, and adding two more in June 2020. I use them to the max daily, so this is quite encouraging for longevity.

Is there a reason for a 15 cell design over a 16 cell? I understand that DC voltage is then slightly lower which has a few drawbacks, but is there any chemical or electric reason why LiFePO4 cells enjoy being wired as 15 cells better?

Does it perhaps have a measurable impact on the cost of the DC components used inside the battery?

Or is it really just the “corporate” reason that it is less easy to steal their BMS because it is built to manage such a non-standard setup?

Yeah similar story on my side (I only have 2 though). Very pleased with the batteries thus far. I do think they will be at their happiest in a 5kVA inverter/100A MPPT setup with 3 in parallel. Even better if there’s 4.

Oh yes, and when I said that I think the Pylontechs will perform better relative to other batteries than in those tests due to the strict limits, I don’t mean that they will perform absolutely as well as in those tests, just relative the other batteries in exactly the same conditions as they are in. Lab conditions presumably regulate temperature as close to optimal as possible (so that it isn’t a factor in the conclusion reached).

The only reason I can think of is it must be slightly cheaper to manufacture ![]()

And they use pouch cells. Here some inside looks of the unit. Pylontech US2000 Plus Teardown - Batteries - Power Forum - Renewable Energy Discussion

Reading the summary on the Choice article they made reference to batteries failing during the summer. I therefore think they used the lab to duplicate expected temperatures in the Australian environment. The lab tests they are performing will be harder on the batteries as they are cycling them 3 times a day.

Ah interesting. So cycling them three times a day will generate quite a bit of heat and if that heat isn’t disposed off actively, this will be quite the strain on the banks. Especially if they are simulating Australian temperatures in the lab environment.

I’d expect a lab test should really only test one thing, so that the impact of it can be isolated. However, if you want to do a long term test, maybe it is best to just test a scenario. You might not be able to conclude which batteries have the best longevity in perfect operating conditions, but you would be able to conclude which is best for the scenario you simulated.

In that respect I think Australia is probably a good proxy for SA and that cycling them three times a day especially in summer ambient temperatures, will not simply be a light tickle for the cells.

I actually haven’t read the article, but every now and then I read the reports on the battery test centre. I believe that the data for the article would come from there.

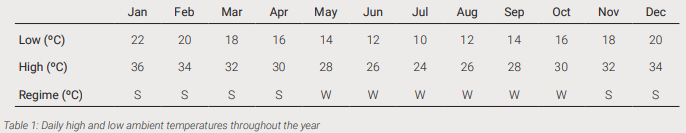

The ITP lithium-ion battery trial aims to test batteries in ‘typical’ Australian conditions. It is expected that most residential or small commercial battery systems will be sheltered from rain and direct sunlight, but still be exposed to outdoor temperatures; therefore, the ambient temperature in the battery testing room is varied on a daily basis, and varies throughout the year. The high and low temperatures are given in Table 1.

ITP implements ‘summer’ and ‘winter’ temperature regimes for the three daily charge/discharge cycles. In the summer months the batteries undergo two cycles at the monthly high temperature and the third at the monthly low temperature, and in the winter months the batteries undergo two cycles at the monthly low temperature and the third at the monthly high temperature.

Here’s a screenshot of that table:

So they do 3x cycles of the battery per day. In January (Summer) they have 2x cycles at 36 degrees and 1x cycle at 22 degrees and in July (Winter) they have 2x cycles at 10 degrees and 1x cycle at 24 degrees.

Between Augut 2020 and Jan 2021 I installed 3 Pylontech’s - also only 1% drop so far. Like you, I use them to the max every day - down to 20% SoC

Perhaps that SoH figure is that a time dependent deterministic calc. Or do you think the BMS is able to actually calculate it?

Interesting question. I suspect they calculate it somewhat. A user who uses it to the max each day will drain the SoH more than someone who uses it for backup only, right?

I am closely watching mine every day, to see exactly when it will go down an additional 1%.