Now this is something you should be able to source in Lusaka??

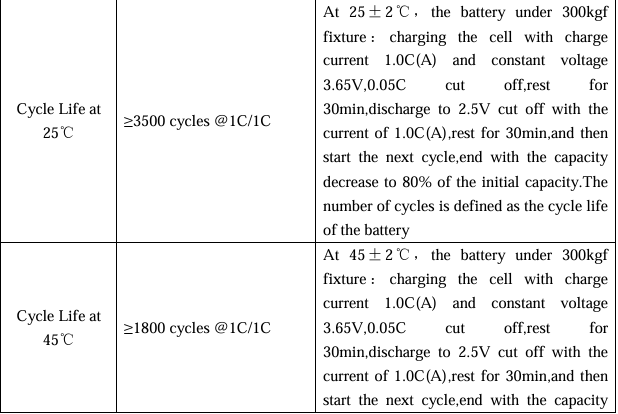

It is common to clamp the cells because the data sheets of many cells specify the cycle life while clamped with x amount of force.

Like this, where they spec. 300kg of clamping force.

This discussion about the battery came up, after the AI171 crash. Some bloke on Youtube opined that what happened was some diode failed, causing the battery to overcharge, causing a short, causing the 24V DC bus on both sides of the plane to be pulled down, which is also the supply that 1) powers the optocouplers that reads the position of the fuel switches, and 2) powers the relays that opens the fuel solenoids.

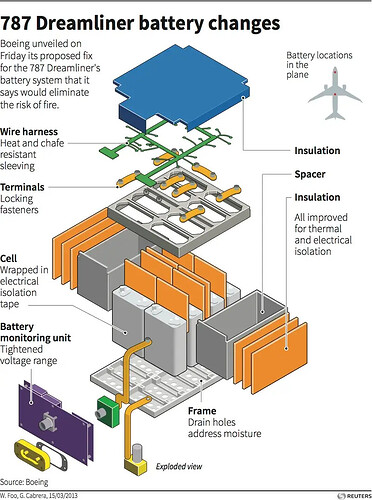

Of course the entire thing is nonsense, the lithium battery is literally used only when black-starting the plane, or for running lights while being pulled by a tow truck, and it powers only the captain’s side. The entire electrical system is specifically designed to have everything redundant (two alternators in each turbine, two power conversion units, everything redundant, plus two switches so you CAN bridge the 24V between captain and first officer manually in an emergency… although that is not what happened in this case. I digress. Anyway… so that is when I heard that there was an incident with a burning battery in a 787, and now the thing sits in a stainless steel box vented to the outside of the plane, and they have space between the cells to prevent thermal runaway from spreading to adjacent cells.

Some details here and here, but nothing about the cell spacing specifically. Google images brings up this:

Interestingly, this doesn’t actually indicate that the cells should not be compressed, merely that insulating material should be added to prevent thermal runaway from spreading.

So quite likely, this does not solve your problem at all ![]()

Bought some batteries that apparently came out of a EV vehicle.

Got them in “modules” of 4 cells in their OEM plastic casings.

Lots of ventilation allowed.

Busbars where perfectly inserted in plastic casings, solid busbars.

So some cells did expand.

They pushed into the spare spaces between them until they pushed the plastic holder apart.

The busbars stayed in place. If left as is and still charged, over time they would have torn out.

Here is the conundrum I deduced:

IF your cells move for whatever reason and you have sold busbars, that could be very bad.

So you clamp them.

Especially in a vehicle.

OR you use braided busbars to allow for movement.

Sorted.

But there is a 2nd teeny weeny detail - temp. Lifepo4 does not like temp.

So you leave space open between the cells to keep them room temperature.

You can space them with solid busbars.

Or braided.

But in the end, the cells should not move. That is never a good idea.

Hence those OEM plastic casing per 4 cells was such a grand idea.

Vented.

Not moving anywhere.

Using solid busbars or not, makes no difference.

So I just spoke about plastic OEM casing that is vented. Keeps the batts cooler.

But the manual says:

That also confused me at the time.

How do you measure? Google gave info BUT you have 6 nuts per side to tighten.

"Wat nou”!?

What tools where and how?

So engineer tells me, relax, tighten then with just your fingers. Should be close to the specs.

Cool, then my next question - still don’t know:

Must the cells be at 50% or 20% when you clamp them?

Or clamp at 100%.

Cause between 20% SOC and 100% SOC, the cells are not the same size.

In a vehicle, crash safety is the more important part. Part of testing a battery involves literally dropping it (in a specially designed test rig) and subjecting it to a 50G deceleration. Nothing should tear free. You can’t have modules or cells tearing off and short circuiting. This video is in Czech, but with english subscripts, he explains why you can’t just swap in any replacement battery and expect the safety margins to remain the same.

I have to add, that the battery he is talking about (the Martigi battery) has improved a lot. If anyone reads this and think I’m against that particular replacement, I’m not, this is an older design that was not safe.

He also talks about how such batteries are stacked in scrapyards.

You calculate a torque value from the nut size and the pitch of the thread. Tables exist with “nut factors” that help you do this.

I am working on my project in the Western Cape.

iirc the strapping/compression is to prevent/manage delamination between the internal layers of the cell as it expands. Therefore, it would likely make most sense to clamp in the least swollen state?

I did mine, instinct, at SOC of 20%, finger tighten the nuts as best I can.

When the bank is full, no chance to loosen those nuts without a spanner.

I tried.

Titbit:

Watched a German scientist discussing Lifepo4 and compressing.

He said that when those molecules, yes molecule level, start to expands, there is nothing that is going to keep them compressed together.

Made sense. You have actual molecular science and then you have what you hope to achieve in the real world.

Took the middle ground - tighten by hand at 20% SOC and hope for the best.

The batt kept as close to 25 deg C as I can without a aircon.

I thought it was at 50% SOC ? Is there any source of Poron here in SA ?

If you are referring to the clamping it is easily above 3.2v.

But now I’m doubting myself … maybe I must redo it at 50% SOC.

Some cells’ literature state that they should be between 30%-40% SOC when they are clamped. The clamping debate is almost as volatile as the engine oil discussions on car forums. The effects of what you do/choose will most likely only become evident long after the fact and at that stage technology has progressed and you will be in a whole new discussion.

Alas, I am still confused on both topics ![]()

I think the rationale on clamping at a given SOC is that if you clamp at 100% then as the SOC goes down the cells relax and the cells become somewhat looser - at the other end if you clamp at 10%SOC as the cells charge they will expand and possibly cause damage because there is no room for them to expand into.

As you say, an endless argument - I guess its like are you a Republican or a Demorat ?

Hah! Yes, some people are still convinced Castrol will cause sludge buildup. It isn’t as if the entry level oil has moved from API-SF to API-SL over time… they will still tell you this…